All products have passed various types of global Tier-1 certification testing

Tidesolar Philippines was founded in 2024 as a premier module manufacturer encompassing production, sales, and service, with a brand-new technologically most advanced production line. The annual module production capacity is 2GW, specializing in the latest and most promising N-type TOPCon modules. Our focus is on the manufacturing and promotion of core solar power generation products, offering customized solutions tailored to our clients' specific needs.

Tidesolar Philippines has established a "vertically integrated" production capacity from silicon, silicon rods, silicon wafers, cells to modules in the industry, and is committed to building a new energy ecosystem and contributing to the global energy conservation, emission reduction and energy transformation cause.

Our factory is located in Batangas of the Philippines. We own four production lines, two lines of the solar cells and two lines of the solar panels with an annual capacity up to 1GW. We aim to provide our clients with full industrial chain products and service, to meet various needs from them around the world.

Mouse Drag

Mouse DragAll products have passed various types of global Tier-1 certification testing

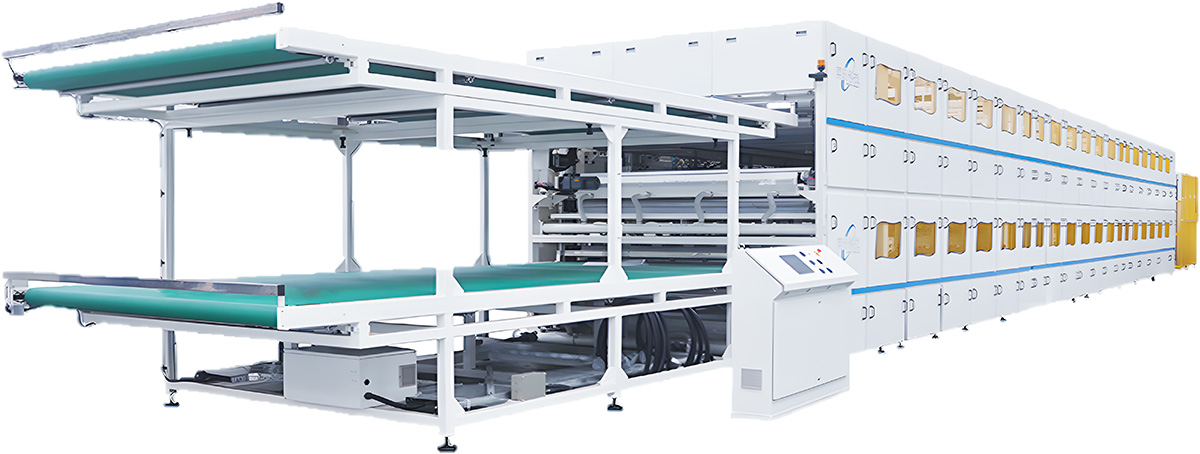

Al-powered visual intelligent detection system is used to detect defective module products, replacing traditionalmanual detection and judgment to improve testing efficiency and yield.

Precision positioning welding is used to achieve milimetre-level precision positioning in MBB module production

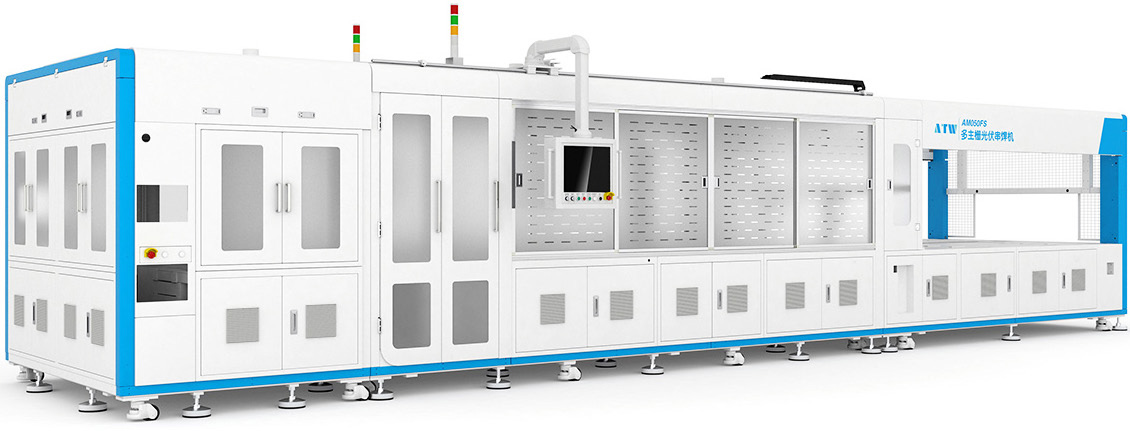

Integrated Cutting and Series Welding Machine

Small footprint with large production capacity, ultra-low module process energy consumption, fault self-adjustment and repair, 5G information control management system, low labour costs.

Integrated non-destructive cutting and automated series welding for photovoltaic crystalline silicon solar cells, thisequipment features high productivity, high precision, and high compatibility, and is compatible with various serieswelding processes such as SMBB and 0BB